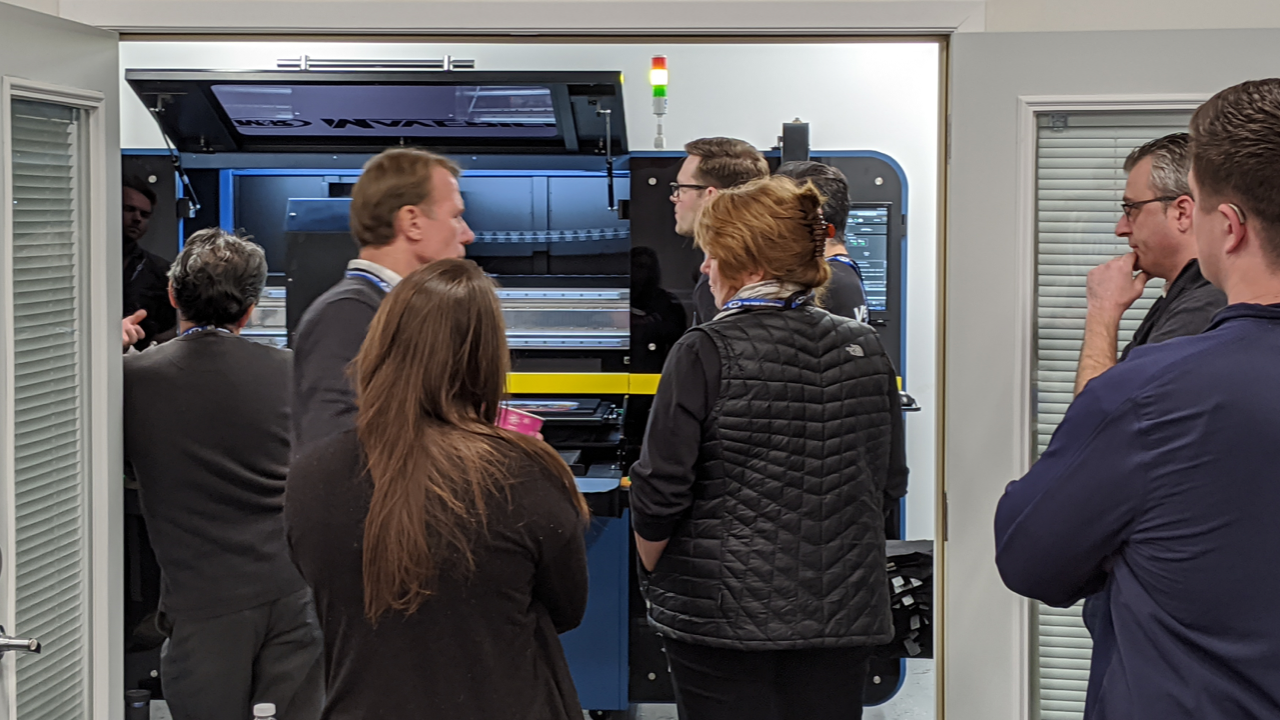

Located just 20 miles outside of Chicago, Printavo’s home city, The M&R Companies headquarters is a massive 320,000+ square foot screen printing machine manufacturing facility. It’s a fitting home for one of the world’s most respected screen printing manufacturers, and we’re fortunate that they’re right in our backyard. We took the short drive to M&R for T&J Print Supply‘s Vision 2020 event, held in early November 2019.

The purpose of Vision 2020? Show M&R’s newest advances in digital and hybrid textile printing and prepare some of the area’s leading screen print shops for the changes that will rock the custom printing industry in 2020.

To summarize the major points of Vision 2020:

- The industry, as a whole, is moving toward on-demand digital printing business models

- M&R is expanding its DTG offerings to offer print shops access to these new business models

- Digital printing technology (like M&R’s new Maverick DTG) is now fully mature

- The actual number of t-shirts being printed isn’t changing–but how they’re printed, purchased, and delivered has completely shifted in the past ten years

- Screen printing vs. DTG is a false choice: screen printing is still thriving and is not going away. Hybrid printing may be the best of both worlds

- M&R is very sensitive to trends in the industry. DTG is now the fastest growing component of the industry by a wide margin

- A select few shops will take advantage of this technology and benefit tremendously from a first-mover advantage

About 18 months ago, Danny Sweem took over The M&R Companies as CEO. Editor’s note: we more recently interviewed M&R CEO Danny Sweem after coronavirus shut down the global economy in April 2020.

After 30 years as CEO and founder at M&R, the legendary Rich Hoffman decided to retire from his post. Many in the industry feared the worst for M&R. Virtually every screen printer knew Rich and his remarkably kind demeanor. Mr. Hoffman’s reputation was as rock-solid as M&R’s brand.

What could have been a dramatic handoff turned into a pivotal moment for the company. Mr. Sweem has proven himself more than capable for the job. The company has doubled down on its marketing efforts, outreach efforts, educational content, and has begun searching for its next phase of growth.

With a soft-spoken cadence and a native South Carolinian accent, Mr. Sweem was not shy about his love for textile printing. “T-shirt art is the best canvas, T-shirts are Americana, and they’re not going away,” Mr. Sweem proclaimed. It’s obvious that Mr. Sweem takes the mission at M&R very seriously.

With roughly 650 employees at two manufacturing facilities (one outside Chicago and another in Poland), The M&R Companies have sustained their business through an open culture of ideas and debate. “I’m not thin-skinned,” Mr. Sweem proclaimed. “Speak your mind, get your ideas on the table, trust each other.” As they work to create a balance between technology and creativity, the team at The M&R Companies are obviously capable for the myriad challenges 2020 will bring.

Editor’s note: take a look inside M&R with our tour video (and if you’re ever in Chicago, make it a point to visit).

Tectonic shifts in the screen printing marketplace

“The t-shirt is an ideal e-commerce product,” Mr. Sweem explained, “It doesn’t break, it’s customizable, it ships easily, and it’s very low risk.” That means that screen printers are finding print-on-demand business models to be increasingly lucrative, and M&R intends to be there to assist in that process of growth and adaptation.

M&R’s insights into the marketplace are deep since they’re so involved with gauging the industry’s needs and wants. While we don’t want to divulge any sensitive information about the company here, we will say that Mr. Sweem was remarkably candid. He divulged M&R’s revenue targets, its current state, and where it sees growth occurring throughout the industry.

Their foray into hybrid printing with the DS-4000 “Digital Squeegee” was no accident, and first-hand experience has shown the devices to be capable of 2,000 prints a day with negligible downtime. Same Day Tees’ Pete Bolsoni was on-site to give his candid take on the Digital Squeegee: “It allows us to do three to five simulated process jobs in a day, when before we were doing one or two.”

Editor’s note: the photo above is a screen printed sample from a shop with a Digital Squeegee. It looks like embroidered-on jeans–and feels like it, too. But it’s just a hybrid screen print done at integritees in Texas. This is easily one of the most immediately impressive screen prints we have encountered, and it’s just a taste of the wildly creative things that are possible with this sort of t-shirt printing technology.

The way forward: education and innovation

The M&R Companies have a unique, multi-pronged growth strategy that Mr. Sweem was willing to share. He articulated that it primarily focuses on providing the best-in-class textile printing machines and support while investing heavily in research and product development. With their new digital printing capabilities (thanks to expert staff from recent acquisition Novus) The M&R Companies have their first genuine digital printing engineers.

They believe screen printers have a unique advantage in a rapidly growing consumables market. For some context, Mr. Sweem informed us that e-commerce growth for t-shirts far outpaces the (already high) growth rate for “traditional” e-commerce.

The M&R Companies’ business model is shifting because of massive changes in how t-shirts are printed, distributed, and sold. The actual number of t-shirts sold hasn’t changed much, but the details of how they’re ordered, shipped, and delivered is completely different than just 10 years ago. That change is a tectonic shift in the marketplace, but Mr. Sweem is upbeat. “It’s only frightening when you don’t have a way to deal with the change.”

The “why” behind the Maverick DTG printer

But why should one of the world’s leading screen printing machine manufacturers suddenly pivot to DTG printing?

The truth is that they’re not really pivoting at all. M&R’s new DTG printer, called Maverick, is a natural extension of what they’ve seen in the marketplace.

M&R’s researchers believe that screen printers will be slow to adopt this technology initially. They estimate that perhaps 33% of printers will make a serious investment in DTG, hybrid, and print-on-demand capabilities. But there’s an urgent need for this kind of technology in the marketplace: on-demand t-shirt businesses are now the “norm” to most consumers.

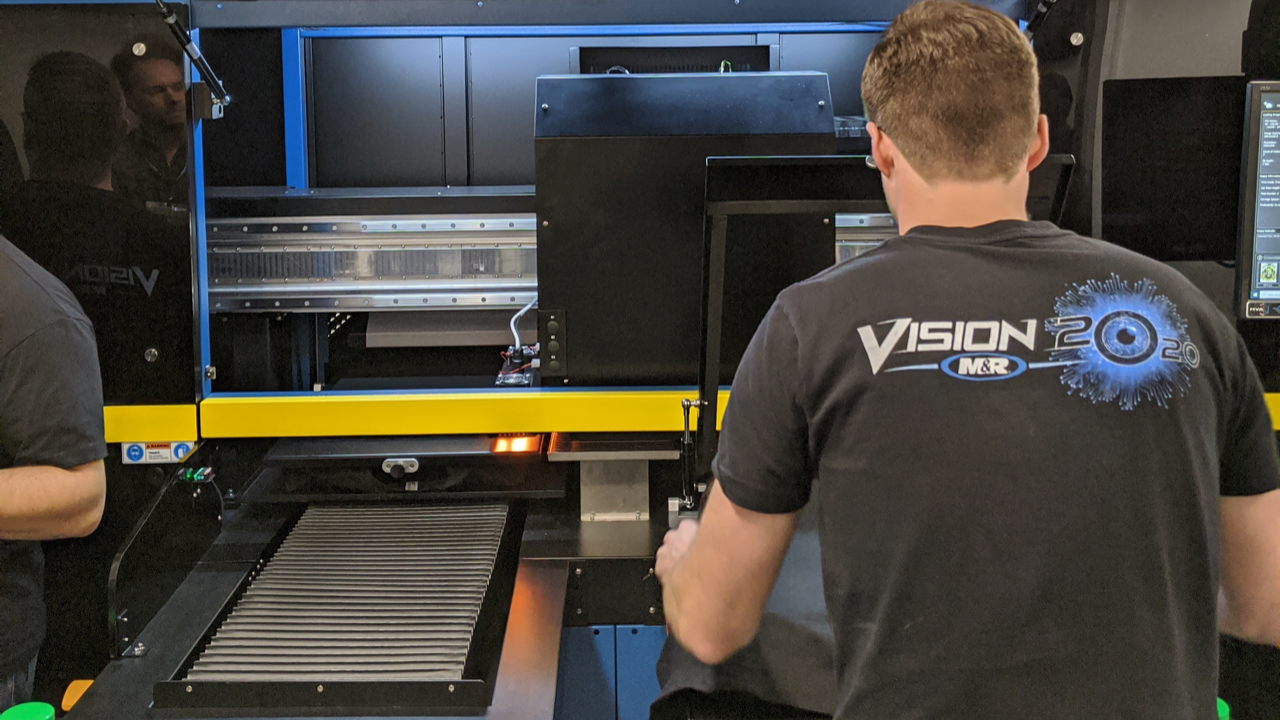

M&R’s Maverick DTG printer is a wake-up call. It clearly underlines the urgency that M&R has observed: now is the time to provide screen printers with a high-quality product that meets M&R’s exceptional standards for durability and usability.

Since this isn’t a sales brochure, I’ll leave you with our general impression of M&R’s Maverick: this is the first DTG machine we’ve seen that looks as capable and (for lack of a better word) beefy as M&R’s traditional screen printing presses.

Maverick looks like it’s built for punishment. It’s built to be in real shops as a tool–subjected to daily wear-and-tear. As M&R’s research and development team piled dozens of black cotton shirts next to the Maverick, the sheer pace of production on display blew away any outmoded notion that DTG printing is slow.

M&R’s plan for the future

How exactly M&R will get opinionated screen printers to accept DTG and hybrid printing (something many screen printers have scorned or overlooked) is a task the M&R team has approached carefully. How does a company like M&R lead its customers to success?

This transition will likely take several approaches, given the diversity among print shops and the various financial and accounting situations screen printing shops find themselves in. Used M&R screen printing machines have a famously high resale value. Screen printers, like any artist or craftspeople, can be fickle about giving up their beloved gear. Screen printing is a well-known and understood process.

M&R intends to make it much easier for screen printers to take the leap: the company has opted to explore a pathway where businesses can trade in their used presses as a down-payment on new digital equipment.

But most crucially, M&R will simply try harder to compete on price in the DTG space. Since they’re a private company in a market with few competitors, M&R has the luxury of competing on price. They’ve also signaled that they intend to double-down on their educational efforts, naming their new educational facility after the late industry legend Joe Clarke. Finally, M&R is exploring creative credit options to ease the financial transition.

This multi-pronged approach–education, finance, upselling, and leveraging the value of their existing equipment–strikes us as a smart approach.

Naming the new era: SM&RT

M&R has coined a term for this new push: SM&RT.

This is part of their ongoing efforts to be an adaptable, flexible, innovative company. Reassuringly, this Thomas Kuhn was cited as an guidepost: “All significant breakthroughs come from break-withs in old ways of seeing.”

M&R is approaching this new push to DTG and hybrid printing as a way to look to the entire industry–from what it can and can’t do, who it serves, how it operates, and what the actual t-shirts look like–as having a unique opportunity to take advantage of these changes.

The M&R team recounted sharing Digital Squeegee prints with a tremendously successful print shop owner. It was his first time seeing the hybrid screen prints, and he was blown away by them–but had a very negative reaction.

The story goes like this: the screen print shop owner had 42 M&R automatic presses and enjoyed tremendous success as a high-volume contract printer.

But when they saw the hybrid prints, they were terrified: “We can’t print like that!” What makes that so scary? Even a shop with 42 automatic presses can’t print as well as one Digital Squeegee can–and the shop owner knew it.

A 22 color print becomes one to three underbase screens and a pass through the Digital Squeegee. The product is truly stunning.

This gets at one of the more interesting discussions about hybrid printing: it lets you quickly become one of the best screen print shops in the world. Hybrid printing is still an exclusive club. But it’s obvious that M&R wants to ensure that club gets bigger and bigger.

Monetize on-demand screen printing or get left behind

“Screen printers are late to the party, so a lot of our customers expect subpar quality. Once customers get the hybrid prints, they expect that quality. It would be really tough to screen print like that, even if you’re one of the top 5 screen printers in the country.” – Pete Bolsoni, Same Day Tees, M&R Digital Squeegee owner. Editor’s note: watch a tour of Pete’s shop, Same Day Tees, here.

The ultimate message from Vision 2020 wasn’t a sales message.

Yes, the event was held to highlight M&R’s Digital Squeegee and Maverick offerings, but it was ultimately a message about survival.

The industry has changed. The technology is here. This is not a question of “if,” and it’s certainly not a question of “when.” This change is happening, it’s well underway, and the major players are not stopping their efforts any time soon. This shift toward on-demand digital printing will put businesses that adapt and explore new options at the front and center of an explosive growth paradigm.

Are you a leader, a follower, or a skeptic? Are you the kind of business owner who will take the risk to sail across the ocean–even if everyone else thinks you’re about to sail off the world entirely? The opportunity to adapt to new technology and adopt it before the rest of the herd is a limited time offer.

No one wants to be the broken record that says, “This is the year digital printing finally takes over!” But when one of the biggest screen printing equipment manufacturers urges their biggest and best customers to transition to DTG and hybrid screen printing – pay attention.

0 Comments