Rick Roth is one of screen printing’s stalwart truth-tellers. A veteran of the trade, Rick is a trusted advocate for the entire custom apparel printing industry.

He writes extensively and hosts discussions on The Ink Kitchen – hands-down one of the most detailed and informative blogs about custom printing on the web. He’s also central to Mirror Image, a high-volume production shop focused on turning out the best possible prints and offering valuable educational resources for screen printers interested in perfecting their craft.

So what’s on Rick’s mind? He wants shop owners to focus on their goals, curing their inks correctly, and nurturing the right customers for their business.

What’s your #1 piece of advice to new and growing screen printing businesses?

“Printing is a system. All the pieces need to fit together. No one miracle ink or press is going to help you. Everything has to fit together. Focus on the entire process, not just one part of it.”

Rick has two pieces of brutally honest advice:

- No magic tool is going to help you. Focus on your process as a whole instead of chasing after a magical piece of technology that “completes” everything.

- If you have a real goal, your decisions are much simpler. Rick always wanted to be the best. But he knew another printer that wanted to be the biggest. The point is to have some goal in mind – because then your decision making is focused and consistent over the long term.

Too many print shops flounder because they’re reliant on the next piece of technology (as Rick called it, “a tech shop owned by a bank instead of a print shop”) or don’t have a vision for what their real goals are.

“The second piece of advice I would give is from one of the biggest printers in Southern New Jersey that was cranking out Iron Maiden shirts on automatics when no one had them. He always wanted to be the biggest. That was his goal. Having a goal makes it easy to make decisions. I always wanted to the best. I want the best press, the best screens. Sometimes I wish I would have wanted to have been the richest. But it helps to have a goal. It makes all your other decisions easier.”

What’s your goal? How are your choices today moving you toward that goal?

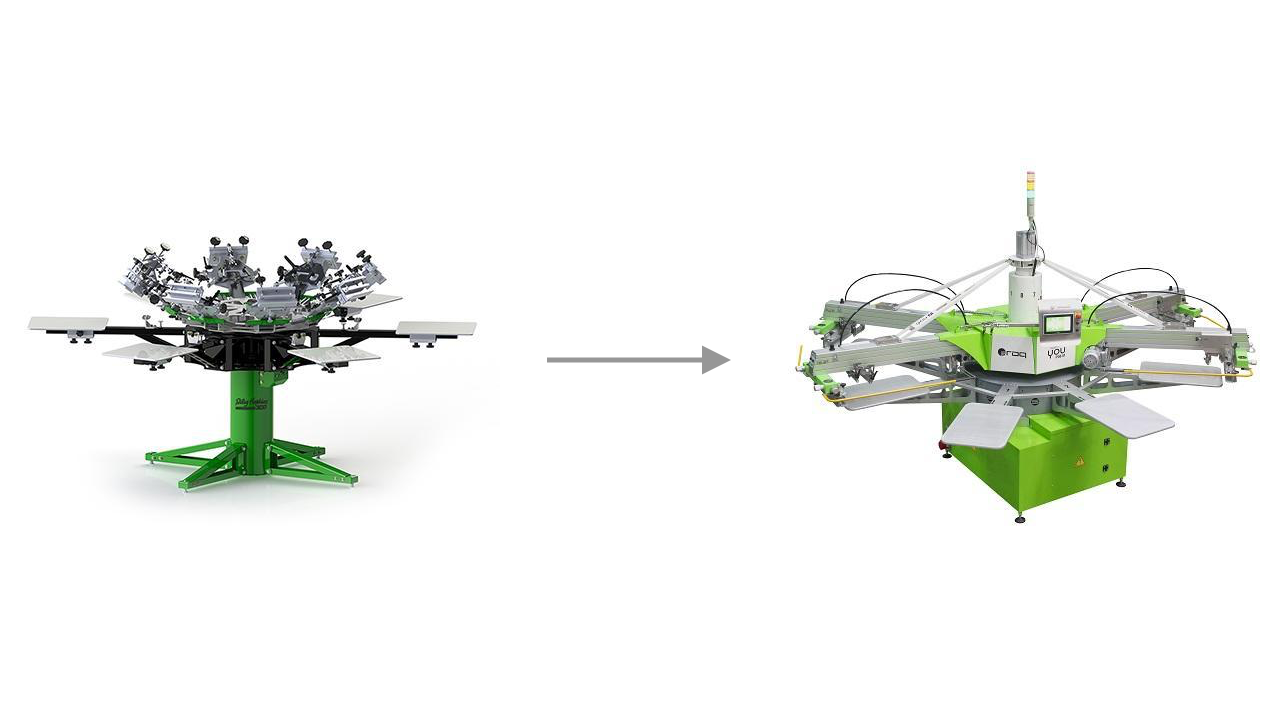

How does a beginning print shop with a manual press make the leap into automatics?

“You aren’t taking in those 400 piece 4-color jobs on black shirts. You can’t do those jobs by hand without giving yourself arthritis in a week. I’m against manual printing in general. It’s really bad for your wrists. That downward pressure, no matter what you do…there’s also not any virtue to it. There’s a lot of virtue to making things by hand in life. But screen printing isn’t one of them. You are trying to print like a machine, but you can’t do it as well.”

Printing by hand is not an advantage. It seems obvious, but Rick tells us that some things in life do have value when they’re made by hand. Screen printing, however, is not one of those things.

But it’s not simple to switch your shop to automatic printing. Your business and clientele have to align so you can print often enough in high enough volumes to sustain your shop.

The simplest way to achieve this? Start subcontracting jobs that are too ambitious for your shop. It’s not something to be afraid of. The relationships you build through contract work can serve you later on. Even if you get that beautiful new automatic press, it’s unlikely you’ll have to stop contracting work out.

“You really need to build out your clientele beforehand. One way to do that is to sub out work. People seem so paranoid about it. A lot of people are afraid of that. There are a lot of trustworthy people in the world. But just being a manual printer and building up to automatic printing? I don’t see it happen that often. It’s very difficult. It becomes a gigantic step because you don’t have the right customers. You want to go automatic, but you have to plan it. You have to get enough work. That usually involves subcontracting work to people you trust.”

How do you find an employee who cares about your business as much as you do?

Similarly to how NFL teams will hire several quarterbacks just to find one that works out, you’ll have to hire and fire fast to find the right employees.

“You have to run through a bunch of people. Some of them aren’t going to pan out. You have to be a little ruthless. Most of your talent is going to come from within. You need to encourage your employees. You never know where a good one is going to come from.”

But beyond that, you also need to focus on giving your employees opportunities to step up to challenges. Rick has found that his best employees typically come from within – you give someone a chance to learn and grow, and they will step up to the plate.

“Finding someone outside? Usually, you have your own way to screen print and decorate. Someone coming from another shop has another way to do it in mind. You usually won’t find the talent unless you build it from within.”

Hiring employees from other print shops can be a crapshoot. If they’re invested in the old shop’s process, they might not be a good fit (even though they have the experience on paper).

Yes, employees are hard to find – particularly great ones. Nurture your people, develop their talents, and challenge them to invest themselves in their work. That’s how to find employees that care about your business.

What are some of the biggest mistakes shops make?

“Some of the biggest mistakes – corroborated by others – is that most people don’t adequately cure the ink. Just because it’s dry to the touch does not mean it’s not going to wash out.”

Rick estimates something like 30% of print shops are not curing their ink correctly! Lots of people trust Rick to visit their shops – even shop owners that keep a tight ship and don’t typically allow visits. So why is curing your ink correctly so difficult? There’s a lot of variables involved that make for real challenges:

- Measuring and evaluating temperatures correctly. Where do you measure the temperature on your dryer? How long is your dwell time? Are you documenting results in a consistent way?

- Weather-based or seasonal challenges. The right temperature in the summertime might not be the right temperature in the winter, for example. Atmospheric pressure, humidity, and temperature can alter curing.

- Controlling variables that hinder consistency. Ink thickness, garment fabric, garment color, power fluctuations, even the temperature of the shirt as it goes into the dryer all have an impact on ink curing.

“On that cold, wet, March morning in New England you set your dryer for a lot different temperature and speed than you might on a dry July day when it’s 100 degrees. There’s no one way to do this. It comes from experience. People want a simple answer. What do I set my dryer for? I don’t know. Figure it out. You have to figure it our or you’re going to send out shirts that aren’t cured.”

So is there a tool for checking whether your ink is cured? Yes! Rick has timeless advice for anyone that wants to figure out whether their ink is cured correctly: “The best testing device in your shop is the washing machine.”

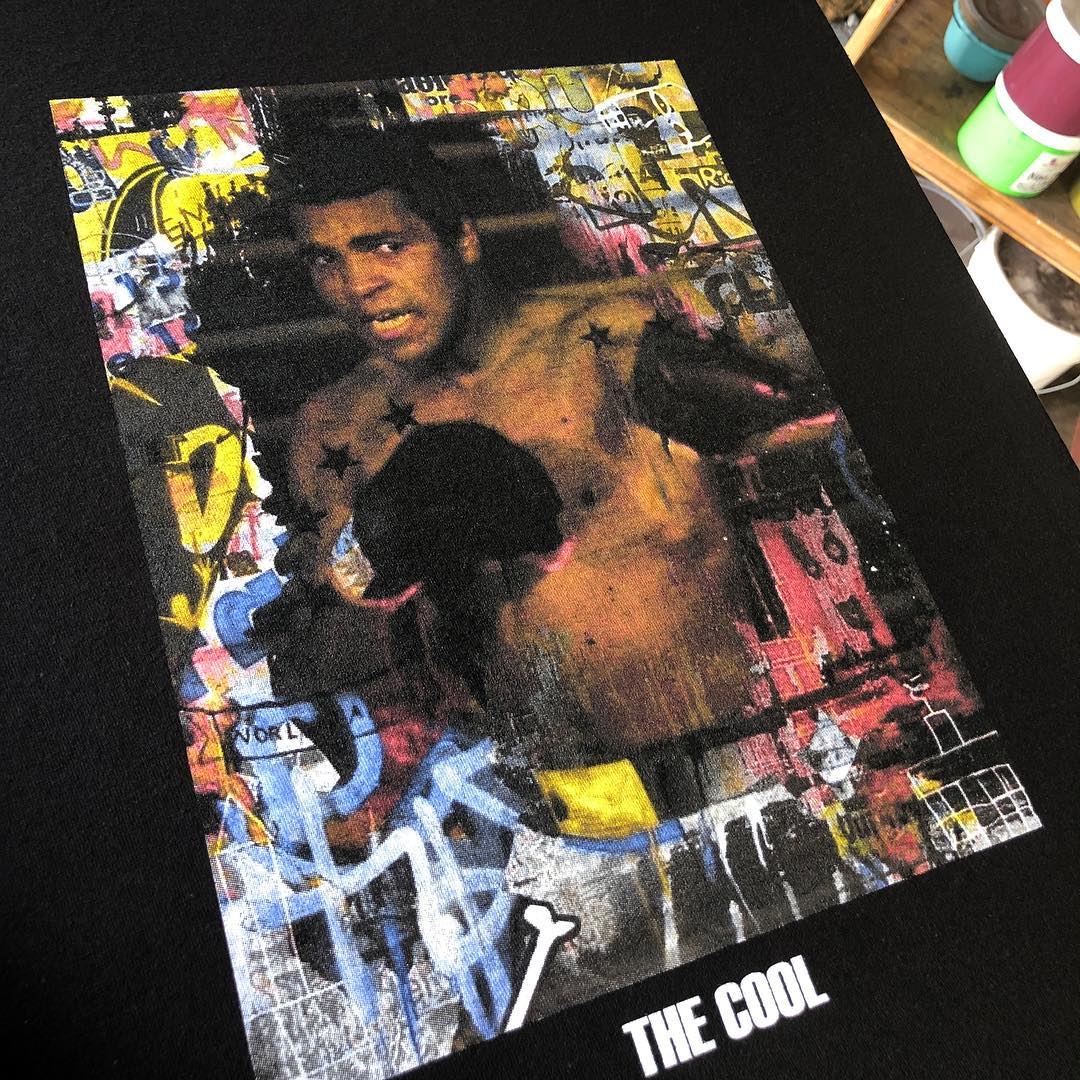

What are the telltale signs of a quality print shop?

“People are hustling. Everything is efficiently in motion. It’s not frantic or crazy. It’s systematic movement. You can tell the difference.”

It’s hard for a full-fledged printing operation not to be a bit chaotic. But the difference between a shop that’s organized its chaos into an effective dance and a shop that’s scrambling just to keep it together is obvious to people like Rick.

Hopefully, you’re keeping an extensive library of great prints you’ve done. But quality can’t be fudged on the dryer belt – Rick wants to see the work you’re putting out on a day-to-day basis instead of your finely curated Hall of Fame. In custom screen printing, results matter more than anything else.

“The main thing is results. I want to see a bunch of samples. I want to see the shirts coming off the belt right now. There’s no proof you’re a good print shop like that. Let’s see the shirt coming down the belt now. Let’s see your best prints. Let’s see a lot of them.”

Do you have any pricing advice for shops?

“You do not want to be the cheapest price. I don’t see that working for anybody. That’s a fast track for going out of business.”

Ah, pricing. Everyone’s favorite topic. We know how challenging pricing your work is – and so does Rick. His advice is simple enough to understand, but harder to really implement: understand your costs, your market, and be able to keep your shop open.

Striking that balance is harder than it seems. Rick doesn’t have a formula, a method, or a straightforward way to know if you have the right prices – no one can do that for every print shop.

Instead, Rick joins the long list of experts that have warned us against the “race to the bottom” mentality that custom apparel printers fall victim to. Yes, the odds are good that someone can do it cheaper than you can. But for how long?

What advice do you have for shops looking to grow their business by acquiring new customers?

“15% of the customers are 85% of the money you make. It’s a lot easier to keep a customer than to get a new one. Word spreads fast when you screw up. New customers are hard to get. Historically, my best customers take 3 years to nurture. That’s a very long process. The person you visit isn’t going to send you all fo the work. Most new customers are going to suck to begin with. But it won’t be terrible forever.”

So you want to make more sales. Guess what? You have to hit the ground and put in the hours. There’s simply no shortcut here.

- Keep your best customers happy. A small portion of your customers will make up a disproportionate amount of your revenue. It’s a fact of life. You’ll have better luck nurturing and growing those accounts. Managing your best customers is as valuable as finding a new one.

- Take the long-term view. Rick says it takes three years before a good customer become a great one. Develop the relationships and remember that the first few jobs may be tougher than the “normal” job that customer would bring you – they may be switching shops, facing a tight deadline, or dealing with fallout from a misprint.

- Go out and find them. You have to do the work to find the right customers. That can be demographic and market research, being present in your community, or getting help from a marketing and PR firm.

- Prioritize the customers you love. If you have a customer you really love to print for, make them loyal. Don’t BS people about loyalty and service unless you mean it – and can back it up with action.

Rick relays an anecdote about a small shop that spent 4 days finding whether or not they need safelight covers. “Dude. You should have gone out for 4 days and looked for customers. You could have paid for a thousand safelight covers with that time!”

What’s the biggest production bottleneck that you see frequently?

Bottlenecks persist. If you fix one, another appears. With that said, the worst bottlenecks seem to occur due to poor setup practices and an inefficient screen room. But fixing one bottleneck might reveal another – there are limits to how fast any given part of your shop can realistically operate.

“If you fix one bottleneck, you’ll get another one somewhere else. If you make screens faster and print faster, eventually you’ll not be able to do your art fast enough. If you get your art faster, eventually your customer service people won’t be able to keep up.”

Rick doesn’t want shop owners to focus on how many “prints per hour” their press can do. It may not matter much if you’re spending a lot of time on setting up and breaking down jobs – or if your screen room can’t keep up with demand.

“Setup time is the worst bottleneck. Either people aren’t trained, they don’t have the right materials…you have to have equipment that works, organized ink, screens that are right – or you can’t setup quickly. Most people don’t focus enough on setup. They’re worried about how fast their press will turn. That’s negligible. It’s all about how fast you setup.”

If you want to have a successful workflow for setup, you’ll probably need some standards. Whether that’s a kit that each worker in your shop gets, a checklist for setting up jobs, or highly specialized roles that focus on one aspect of production – finding bottlenecks in your production and eliminating them in a sure-fire way to improve your business and think about your process as a whole.

Where do you recommend people go to get screen printing knowledge?

The Ink Kitchen! Rick laughs at this suggestion since it’s his site – but in all seriousness, check it out. They’ve got some of the most valuable info for screen printers out there. It’s authentic, detailed, truthful, and updated often.

“Don’t trust one resource, you’ll have to see through a lot of bull. There’s no college, no one thing. There’s not one source. Trusted vendors are an important vendor, but if you only listen to them you’re crazy. You need to go shows, you need to talk to your peers. You need to be part of Facebook. Your spouse, your employees, your family – they don’t want to hear about screen printing.”

So who can you rely on? First, start with trusted peers. There are dozens of Facebook groups for screen printers and shop owners that can act as an outlet for frustrations – and a way to check whether you’re on the right track. Rick says that being secretive isn’t the right path. Instead, shoot to be open and even vulnerable.

Sharing your “secrets” isn’t a real threat, but avoiding friendships and relationships that can help your business because you don’t want to give away your “secret sauce” is a real threat. You are not in this alone!

Rick has friends that screen print across the world. By looking at their concerns and seeing the issues they face, he gains a broader understanding of the issues he should be concerned about.

A huge thank you to Rick Roth for sitting down with us at ISS Long Beach and sharing his knowledge.

This is the second in a series of interviews with high-profile screen printers and shop owners. We’ve asked them for insights into growth, hiring, printing, pricing, and production. The level of truly valuable information in these interviews is astonishing.

Last week we shared our interview with legendary author, consultant, and printer Scott Fresener. Be sure to watch our YouTube channel for the latest videos and interviews!

We’ll publish a new interview next week with another expert. Stay tuned!

0 Comments