Ryan Kasparian (from coveredin.ink) took the leap to his own consultancy in 2020 after a storied 20+ year career in screen printing.

Cutting his teeth in Chicago’s bustling Culture Studio and Denver’s high-tech Denver Print House, Ryan’s experience in the industry revolved around high-volume shops that feature lots of employees under tremendous pressure each and every day.

So why go out on his own?

Ryan wasn’t a fan of the industry’s old standard of “keeping your cards close to your vest,” preferring to share his knowledge for free. After prodding from Printavo’s own Matt Marcotte (and the help of a 40th birthday) Ryan decided to start his own consultancy.

So far it’s going great, with his schedule filling up and the shops under his tutelage growing as fast as they can handle.

“The best jobs are the ones we don’t remember. That means the system worked from top to bottom.”

Production management for screen printing: Ryan’s big lessons

Over the past 20+ years, Ryan has learned that production management is a delicate balance of people and process. “It’s a painful lesson, but the best printers are not necessarily going to be the best managers,” Ryan reminded us. “You need a gut punch sometimes to get into gear.”

Scheduling is everything

When scheduling goes smoothly, chaos become a way of life. Ryan recalls joining Culture Studio in Chicago, a formidable scaled-up operation that pushes through millions of prints a month. Ryan cut his teeth with Joey Santo, Culture Studio’s leader. “He’s an incredible trainer and teacher,” Ryan said. “He’d be perfectly calm, thinking about the next 300,000 garments that need to get out of the shop. He taught me to think ahead.”

Maintenance and cleaning are just another job to schedule

Find it hard to keep up with maintenance and routine tasks? These are mission-critical jobs that are part of production management, Ryan told us. “Schedule maintenance just like another job in your shop,” Ryan said. From your presses to your dryers, most equipment needs (at a minimum) weekly inspections and cleaning to operate at their highest level. Catastrophic downtime from machine failure can be almost entirely mitigated by good maintenance scheduling.

Put maintenance tools and setup tools onto the same carts you use for t-shirts

If you use carts in your shop, Ryan has a great tip: put everything your team needs to do maintenance and setup on a cart. The carts usually have t-shirts, inks, job specifications, and so on – but Ryan simply inserts a maintenance or setup cart into the mix. “They never have to stop and know exactly what’s next – it’s like that cart just triggers them, and the maintenance happens,” Ryan explained.

Schedule one hour a week for cleaning

“I like Wednesday, because on Monday everyone is slow and on Friday everyone is goofing off,” Ryan told us when we asked which day is best for cleaning. He doesn’t suggest going too far beyond an hour, since you should have scheduled maintenance as part of the daily routine in the shop anyway. This one hour period is an opportunity to clean hard-to-reach places and other high-traffic areas that get neglected.

The owner has to step back from production

“Look, the owner shouldn’t run production past a certain point,” Ryan said. We pressed Ryan further for clarification and he explained that there are certain parameters where an owner is actually hurting the business. The owner should step back when:

- 6+ employees are involved.

- 2+ automatic presses are involved.

The reasoning here is that the owner is task saturated with other aspects of the business when they reach this scale. “It’s surprising to most owners, but they’re probably going to screw things up more than they’ll help [at that scale],” Ryan told us. There’s simply more valuable things an owner can do than manage production.

Hiring a good production manager

We’ve discussed how Printed Threads used a production manager to dramatically change the shape of its business before. They successfully hired an industry outsider that took the production management responsibilities away from the owner (and improved the speed and accuracy of their production in the process).

Ryan told us that a good hiring manager will justify a high salary.

How much should you pay a screen printing production manager? The numbers are in the $60k to $100k range, depending on your location. “Efficiency gained really justifies that kind of salary,” Ryan said, explaining that the production manager takes on a hybrid role in the company, juggling people and printing: “They’ll really be 50% focused on printing and 50% focused on the staff.”

The biggest problems that print shops have: Ryan’s perspective

Ryan said that three persistent issues crop up again and again in the screen printing industry: mismanagement, a lack of training, and a lack of experience.

Mismanagement

Whether it’s a production manager not getting the support they need from the owner, the staff not getting the tools or help they need to succeed, or an owner that’s not yet ready to manage – mismanagement is rampant throughout the screen printing industry. “Culture just is,” Ryan explained, “it’s not something you can make.” Ryan suggested looking into management coaching and courses to help leaders mature and grow. “HR is not optional,” Ryan urged.

Lack of training

“Look, no one is training anyone, period,” Ryan said. We’ve seen people lament the lack of standards and accreditation in the printing industry, and that’s a valid perspective. Standard operating procedures are impossible to formulate when no one can agree on a standard in the first place – but that’s irrelevant to Ryan.

“It’s tough to write out what your job is, but you have to do it,” he said. He explains that one shop he worked with wrote out SOPs for its SAATI laser-to-screen system. “Now anyone can run this state-of-the-art machine, you can have anyone in the shop make screens.”

Ryan’s tips for training include:

- Making videos. It’s easier to train your phone once than repeat the process dozens of times.

- iPads at every station for communication, QR codes, etc.

- “Kill the question” mentality: “it takes too long to walk around the building, so make the answer come to them by killing the question in the first place”

- Create your own standards.

- Create cheat sheets for simple tasks (such as counting by sixes or dozens)

- “Kill thinking”: make everything process-oriented with clear moves at every stage

Training is more than what an employee experiences in their first few weeks on the job. It’s a holistic process that continues through the employees’ entire tenure. It can be seen and felt on the shop floor.

Lack of experience

Where, exactly, do production managers go to get experience in this industry? Well – they go to a print shop and grind it out. “Are we going to be the gineau pigs?”, asked Ryan.

The only solution is to understand and accept a certain amount of failure. “Do and try things,” Ryan urged. In the end, you’ll only create more experienced workers who have seen what happens when things go badly – but now they’ll be armed with the knowledge and experience to prevent it from happening.

What to fix during the January slow period

“This is the time to go: we suck, how do we fix it?” If you’re bad at some detailed print process, now is the time to nail it.

Got a weakness in your fulfillment process? Start nailing it down. Use the slow period to plan and prepare. This is always easier said than done, so here are some specific ideas that Ryan suggested:

- Do R&D for ink and screens

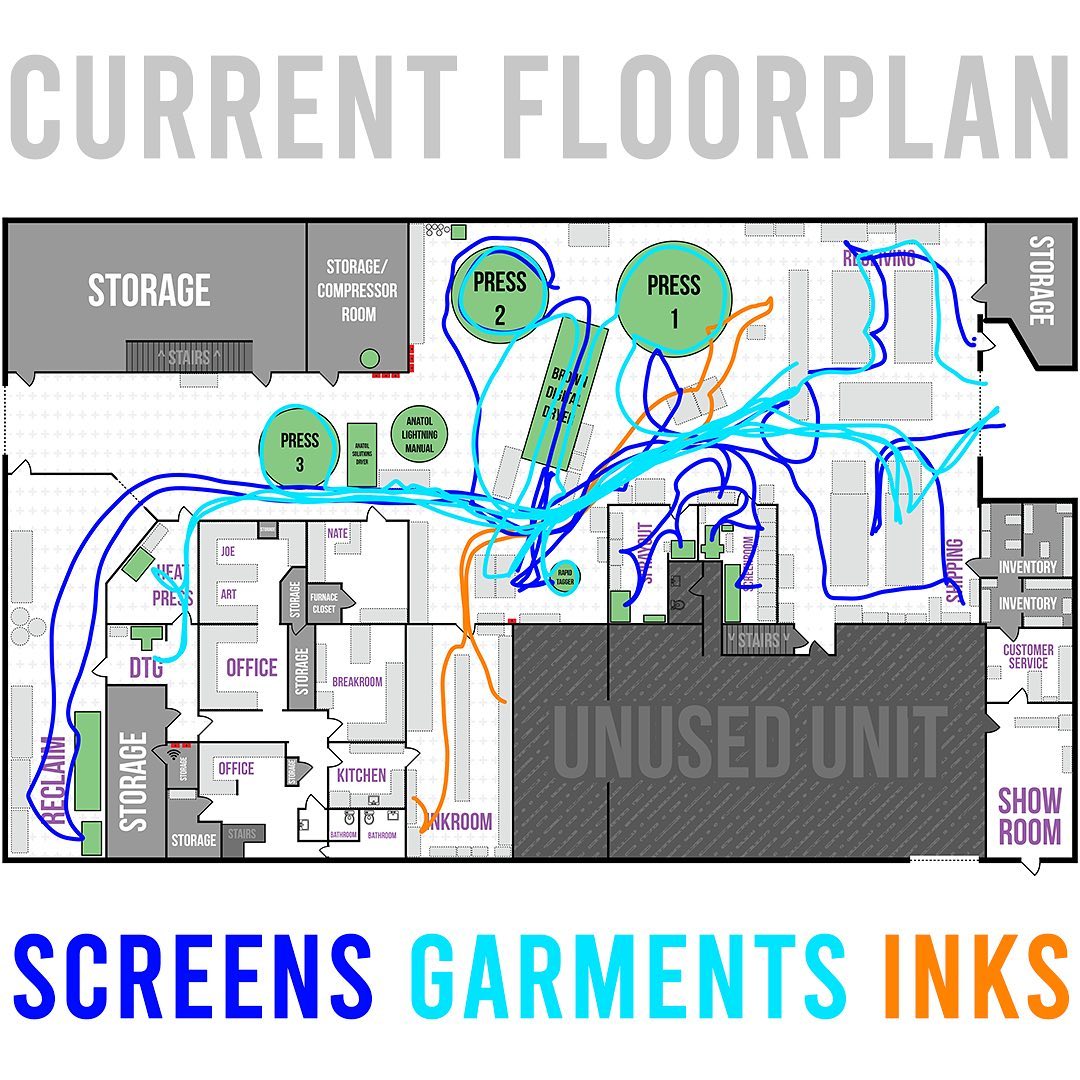

- Maintenance: clean dryers, rearrange shop, clean everything

- Prepare procedures

- Plan management meetings on a calendar

Work with Ryan

Want help from Ryan?

Plan a one-hour discovery call with Ryan at coveredin.ink. All images found on Ryan’s Instagram.

0 Comments