Now that we are through the basics of order intake, we can begin looking at your company’s pre-production workflow. Ask yourself these two questions:

- What am I offering to my customers?

- How can I create a system for seamless, cost-effective and efficient production?

After reading through this guide, you will be able to map out the basic steps of pre-production.

Pre-production is one of the most critical processes of any print job. If your pre-production setup is done correctly, the job will run seamlessly all the way through completion. Most preventable mistakes happen during pre-production – costing you lots of money. Spending time now to refine pre-production processes acts like an investment: you reduce the amount of money & time you have to spend later. Plus, we’ve already done the heavy lifting for you!

First, let’s talk mistakes. What are the two main reasons mistakes happen? The production process is broken, or a team member misunderstands the process. It is up to you to create a process that eliminates mistakes – and then train your people to follow your process properly.

Tips for developing a rock-solid pre-production process:

- Avoid abbreviations: they create errors and confusion.

- Iterate your process: revise to your process monthly or quarterly. Sit with your team to hear how they would improve their part of your process.

- Create a list of tasks employees should NOT do: keep them focused on specific tasks that pertain to their role.

Implementing an effective pre-production system requires thorough training for all of your shop employees. We all want our shop to be operating at full efficiency, like a well-led boat rowing toward the Port of Profit. If your team is rowing at different speeds and in different directions, your boat goes nowhere. You want zero friction between your team and your process. Create predetermined, agreed-upon roles for pre-production. This allows you to train your team effectively – and to hold your employees accountable. Keep everyone rowing at the same speed toward the same goal!

This list will cover pre-production procedures for screen printing, embroidery and sign printing (while assuming your initial artwork and quote has been approved). Every workflow is going to vary from shop to shop — and that’s okay. Spend time writing out what works best for your workflow, making sure to add specific team members by name or department. Pre-production is where the most costly and time-consuming mistakes are made in this industry: be extremely thorough.

Manually plot out your workflow. The first step in developing a pre-production process is creating a workflow. Here’s the foundation of our own pre-production workflow:

- Screen printing:

- Proof the artwork

- Request approval of your mockup or proof

- Finalize the artwork & plan screens (if rejected, revise until approved)

- Order goods from vendors

- Receive and check-in goods

- Print films

- Send films to production

- Check-in films

- Burn screens

- Embroidery:

- Proof the artwork

- Request approval of your mockup or proof

- Finalize artwork (if rejected, revise until approved)

- Order goods from vendors

- Receive and check-in goods

- Digitize artwork

- Sew out a sample for approval

- Signs/Banners:

- Proof the artwork

- Request approval of your mockup or proof

- Finalize artwork (if rejected, revise until approved)

- Set media

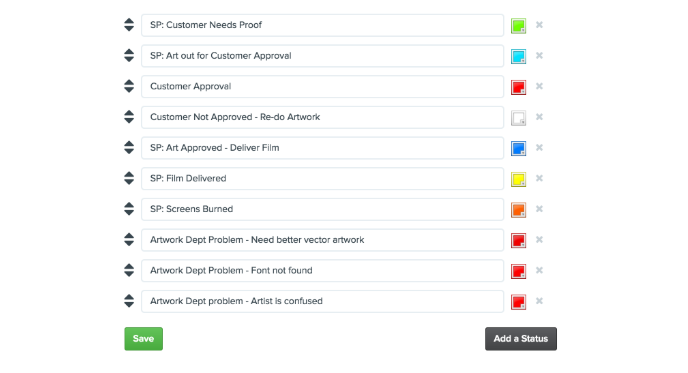

By developing color-coded status updates, we’ve designed a production process that allows us to completely customize, manage and control the workflow. We eliminated guesswork around where exactly an order is, reducing missed steps in the production process. Here’s how one shop set up their color-coded workflow in Printavo:

Notice that these are progressive stages of the job status – not individual tasks.

Develop and assign specific tasks for each step. After you have created your initial workflow, break down the individual tasks required for each step and assign these to specific team members. You’ll have measurable expectations – and ensure each team member understands their exact role in the process.

Introduce standardized communication practices. Once your order statuses, workflow and individual tasks are assigned, set up a standard communication system. Whether it’s emails or in-office messaging, establish exactly how and when information is passed along the chain. Then your team knows the specifics about how and when to expect information.

In a short amount of time, you’ve created your pre-production process: job statuses, specific tasks for specific people, and a clear route for communication. Your shop is ready to start rowing. Let’s go!

Screen printing is a multi-billion dollar industry with customers from every part of the world. Every year, thousands of entrepreneurs discover their passion for screen printing – and they want to claim their cut of the billions and billions of dollars spent on custom printed apparel.

But the majority of new screen printing shops fail before they reach the 5-year mark. They fail because of poor business planning, dull branding, and a lack of ability to scale.

Your shop can be different.

This is an excerpt from our book, The PrintHustlers Guide To: Growing a Successful Screen Printing Business. Written by Printavo’s dynamic founder Bruce Ackerman, Campus Ink’s enterprising Steven Farag, and Adam Cook. The PrintHustlers Guide To: Growing a Successful Screen Printing Business is the next generation’s guide for building your own lucrative print shop.

You can purchase a physical copy of the book on Amazon.

Previous chapter: Chapter 14: Artwork

Next chapter: Chapter 16: Post-Production Coming soon!

0 Comments